From Innovation to Industrialization

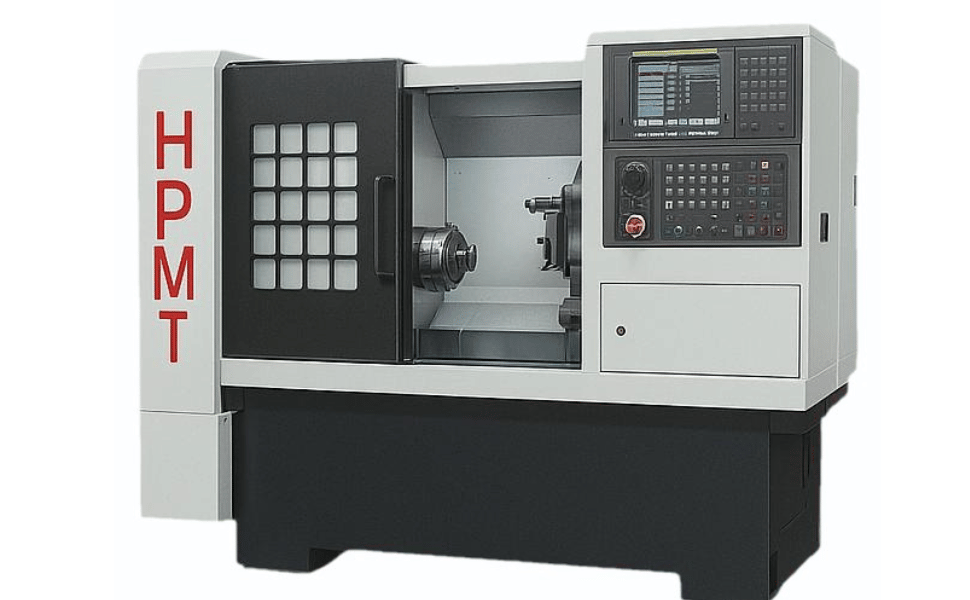

At HPMT Precision Machine Toolings, our New Product Development (NPD) process is designed to transform innovative ideas into high-performance, manufacturable components. Whether you’re developing a next-generation aerospace assembly, a critical medical device component, or a precision fixture for automotive applications, we combine engineering expertise, speed, and production-readiness to bring your vision to life.

From early design sketches to final validation, our team collaborates closely with clients to design, simulate, and refine each component. We focus on performance, feasibility, and scalability from the start — minimizing redesign cycles and accelerating your path to market. Through in-house prototyping, advanced CAD/CAM modeling, and manufacturability analysis, we ensure every product is optimized for real-world production success.

At HPMT Precision Machine Toolings, we don’t just develop new parts — we create smarter, faster pathways to precision manufacturing.

What We Do

Our New Product Development (NPD) Services

At HPMT Precision Machine Toolings, we provide end-to-end NPD solutions designed to turn your innovations into reality — with precision, speed, and scalability at the heart of every process.

Concept Development

We begin with collaborative ideation, technical feasibility studies, and early-stage design roadmaps that establish a strong foundation for successful product realization.

Prototyping & Validation

Using rapid CNC-machined prototypes and functional testing, we evaluate form, fit, and function — minimizing development risks and accelerating your time to market.

Engineering Design

Our comprehensive CAD/CAM design support includes 3D modeling, 2D detailing, GD&T, BOM creation, and complete production documentation, all fully optimized for manufacturability and precision.

Pilot Production

We offer low-volume manufacturing for product trials, regulatory testing, and internal evaluations — executed with the same level of rigor, accuracy, and process control as full-scale production.

Tooling & Production Transition

With engineering guidance and process optimization, we ensure a seamless transition to mass production — including tooling design, workflow planning, and complete production handover.