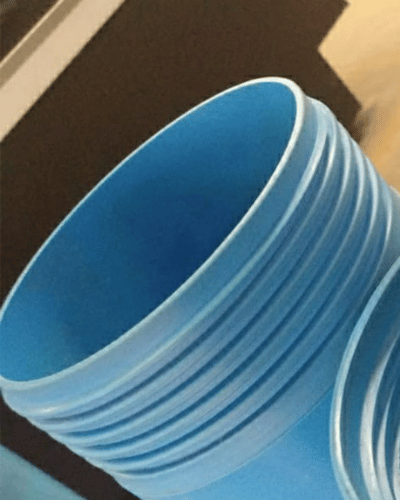

Casing Pipes

Casing Pipes (BHIMA Series)

Built for heavy-duty PVC casing pipe threading, the BHIMA Series combines precision, stability, and high output. Each model delivers smooth, burr-free threads and long-term operational reliability.

🔹 BHIMA-180 (3″–6″ for Casing Pipe)

Specifications:

- Spindle Throughbore – 180 mm

- Spindle Motor – 7.5 / 5.5 kW

- Axis Travel (X / Z) – 200 / 270 mm

- Spindle Speed – 800–1000 RPM

- Tooling System – With / Without Turret

- Work Holding Type – Hydraulic Clamping

Machine Output: 45–50 pieces/hour

🔹 BHIMA-250 (4″–8″ for Casing Pipe)

Specifications:

- Spindle Throughbore – 265 mm

- Spindle Motor – 7.5 / 5.5 kW

- Axis Travel (X / Z) – 200 / 270 mm

- Spindle Speed – 400–500 RPM

- Tooling System – With / Without Turret

- Work Holding Type – Hydraulic Clamping

Machine Output: 45–50 pieces/hour

🔹 BHIMA-330 (4″–10″ for Casing Pipe)

Specifications:

- Spindle Throughbore – 335 mm

- Spindle Motor – 7.5 / 5.5 kW

- Axis Travel (X / Z) – 200 / 270 mm

- Spindle Speed – 250–300 RPM

- Tooling System – With / Without Turret

- Work Holding Type – Hydraulic Clamping

Machine Output: 35–40 pieces/hour

🔹 BHIMA-400 (6″–12″ for Casing Pipe)

Specifications:

- Spindle Throughbore – 372 mm

- Spindle Motor – 7.5 / 5.5 kW

- Axis Travel (X / Z) – 200 / 270 mm

- Spindle Speed – 250–300 RPM

- Tooling System – With / Without Turret

- Work Holding Type – Hydraulic Clamping

Machine Output: 35–40 pieces/hour